Core Technology of Everan

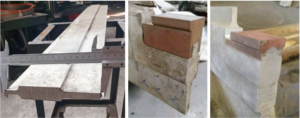

➢ Polymer Material Anti-corrosion Solution Line Coating Technology

After five years of intensive R&D, we've introduced a pioneering technology that offers superior protection against corrosion for anode and cathode sheets in the harshest environments. Our proprietary Polymer Material, characterized by its heat resistance, corrosion resistance, and strong adhesion, provides several key advantages:

- It effectively prevents evaporation corrosion above the liquid level.

- It secures the welding seam, shielding it from corrosive elements.

- It adheres permanently, ensuring it neither detaches nor dissolves.

The adoption of our technology significantly enhances the durability of anode and cathode plates, extending their service life by a remarkable 40%.

➢ Application of Rare Earth Elements in Pb-Ag Alloy

The meticulous selection of high-quality raw materials guarantees a purer final product, and the scientific formula of the multi-element alloy enhances corrosion resistance and durability. The addition of rare earth elements to the Pb-Ag alloy results in notable improvements.

- Firstly, the coarse dendrites are transformed into fine grains. This can improve the density of the anode plate surface, enhance strength, and increase corrosion resistance. The corrosion rate of the anode alloy is significantly reduced, with a 22.12% decrease compared to the corrosion rate without the addition of rare earth elements.

- Secondly, the anode corrosion products are more fluffy and do not form lumps, ensuring the stability of the electrolytic cell pressure.

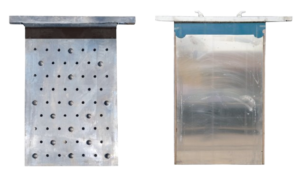

➢ Explosion Bonded Contact Technology

The explosion bonded process generates a "solid state bond" that effectively doubles the Al-Cu bonding area in comparison to standard bi-metal sandwich contacts.

This enhanced bond enables the flow of higher current densities, leading to a marked improvement in current efficiency and ultimately boosting production capabilities.

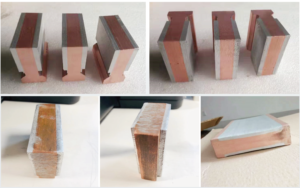

➢ Integral Head Bar Technology

The integral head bar technology directly cuts and processes customized aluminum alloy bar into headbar with hooks and aluminum parts of contact. By combining this with our explosion bonded contact technology, copper materials are directly explosion welded to the position of the conductive head, thus forming an integrated contact.

This technology allows the headbar, contact, and hooks to be produced directly as a whole, eliminating welding seams, preventing the hooks from falling off and improving the overall rigidity of headbar.